The Benefits of Using Cemented Carbide Strips in the Metallurgy Industry

- Categories:News & Media

- Author:

- Origin:

- Time of issue:2023-07-27

- Views:0

(Summary description)Discover the advantages and applications of cemented carbide strips in the metallurgy industry. From increased durability to improved performance, learn how these versatile tools can enhance productiv

The Benefits of Using Cemented Carbide Strips in the Metallurgy Industry

(Summary description)Discover the advantages and applications of cemented carbide strips in the metallurgy industry. From increased durability to improved performance, learn how these versatile tools can enhance productiv

- Categories:News & Media

- Author:

- Origin:

- Time of issue:2023-07-27

- Views:0

1. Introduction: Cemented Carbide Strips and Their Role in Metallurgy

2. Durability and Wear Resistance: A Key Advantage of Cemented Carbide Strips

3. Enhanced Cutting and Machining Performance with Cemented Carbide Strips

4. Versatility and Adaptability: Cemented Carbide Strips for Various Applications

5. Cost-Effectiveness: Longevity and Reduced Downtime

6. Resistance to Extreme Conditions: Cemented Carbide Strips for Harsh Environments

7. Frequently Asked Questions (FAQs)

8. Conclusion: Embracing the Benefits of Cemented Carbide Strips in Metallurgy

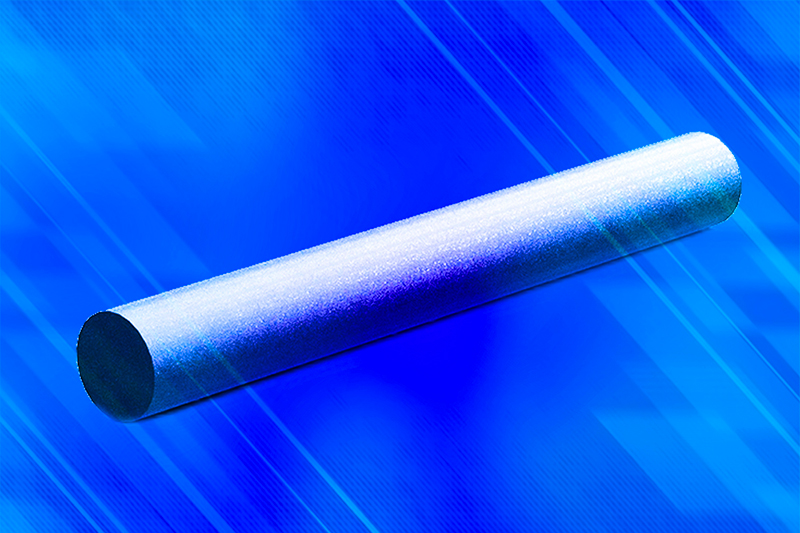

**1. Introduction: Cemented Carbide Strips and Their Role in Metallurgy**

Cemented carbide strips, also known as hard metal strips, are a popular choice in the metallurgy industry due to their exceptional strength, durability, and performance. Composed of tungsten carbide particles bonded together with a metallic binder, such as cobalt, these strips offer a wide range of advantages in metalworking processes. This article explores the numerous benefits of utilizing cemented carbide strips in the metallurgy industry and highlights their applications in various sectors.

**2. Durability and Wear Resistance: A Key Advantage of Cemented Carbide Strips**

Cemented carbide strips have gained recognition for their remarkable durability and wear resistance. The combination of tungsten carbide's hardness, second only to diamond, and the toughness of the metallic binder ensures that these strips can withstand the most demanding machining operations. With their exceptional resistance to abrasion and deformation, cemented carbide strips offer extended tool life, reducing the need for frequent replacements and enhancing productivity in the metallurgy industry.

**3. Enhanced Cutting and Machining Performance with Cemented Carbide Strips**

One of the significant advantages of cemented carbide strips is their ability to enhance cutting and machining performance. These strips exhibit excellent thermal conductivity, allowing for efficient heat dissipation during metalworking operations. As a result, the risk of tool overheating, premature wear, and damage is minimized, enabling higher cutting speeds and improved accuracy. The superior cutting performance of cemented carbide strips translates into increased productivity, reduced cycle times, and improved surface finish in the metallurgy industry.

**4. Versatility and Adaptability: Cemented Carbide Strips for Various Applications**

Cemented carbide strips offer versatility and adaptability, making them suitable for a wide range of applications in the metallurgy industry. Whether used for milling, turning, drilling, or shaping processes, these strips can handle different types of metals, including steel, stainless steel, cast iron, and non-ferrous materials. The ability to tailor the composition and grain size of the carbide particles allows manufacturers to produce cemented carbide strips with specific properties, catering to the diverse needs of metallurgical applications.

**5. Cost-Effectiveness: Longevity and Reduced Downtime**

Investing in cemented carbide strips proves to be cost-effective in the long run. The exceptional durability and wear resistance of these strips significantly extend tool life, reducing the frequency of replacements. This longevity translates into cost savings by minimizing tooling costs and reducing downtime required for tool changes. Moreover, the enhanced cutting performance and improved productivity achieved with cemented carbide strips contribute to overall cost reduction and enhanced profitability in the metallurgy industry.

**6. Resistance to Extreme Conditions: Cemented Carbide Strips for Harsh Environments**

The metallurgy industry often operates in challenging conditions, including high temperatures, corrosive environments, and heavy vibrations. Cemented carbide strips excel in such extreme conditions due to their exceptional resistance to heat, corrosion, and mechanical stress. These strips maintain their performance and dimensional stability even under demanding circumstances, ensuring reliable and consistent results. By withstanding harsh environments, cemented carbide strips enable metallurgical processes to be conducted safely and efficiently.

**7. Frequently Asked Questions (FAQs)**

Q1: Are cemented carbide strips suitable for high-speed machining operations?

A1: Absolutely! Cemented carbide strips are well-suited for high-speed machining due to their excellent heat dissipation properties and wear resistance.

Q2: Can cemented carbide strips be used for both ferrous and non-ferrous metals?

A2: Yes, cemented carbide strips are versatile and can be used for machining both ferrous and non-ferrous metals, including steel, stainless steel, cast iron, and more.

Q3: How do cemented carbide strips contribute to cost savings in the metallurgy industry?

A3: The durability and wear resistance of cemented carbide strips result in extended tool life, reducing the frequency of replacements and minimizing downtime, leading to cost savings.

Q4: Are cemented carbide strips resistant to corrosion?

A4: Yes, cemented carbide strips exhibit excellent resistance to corrosion, making them suitable for metallurgical applications involving corrosive environments.

Q5: Can cemented carbide strips withstand high temperatures?

A5: Absolutely! Cemented carbide strips possess exceptional heat resistance properties, enabling them to withstand high temperatures typically encountered in metallurgy.

**8. Conclusion: Embracing the Benefits of Cemented Carbide Strips in Metallurgy**

Cemented carbide strips offer numerous advantages that greatly benefit the metallurgy industry. With their exceptional durability, wear resistance, and cutting performance, these strips enhance productivity, reduce downtime, and contribute to cost savings. Their versatility and adaptability make them suitable for a wide range of applications, while their resistance to extreme conditions ensures reliable performance in challenging environments. By embracing the benefits of cemented carbide strips, the metallurgy industry can achieve greater efficiency, precision, and profitability in its metalworking processes.

Scan the QR code to read on your phone

Contact

Address : Boyun Innovation Industrial Zone, 346# Leifeng Ave,Yuelu

Tel:+86-0731-88122789

E-Mail :pmcarbide@csu-pm.com

Copyright © Hunan Boyun-Dongfang Powder Metallurgy Co., Ltd 湘ICP备 050020818号

www.300.cn