Products

-

Carbide Rods

-

Carbide Die & Mold Material

-

Carbide Mining Tools

-

Coating

-

Downloads

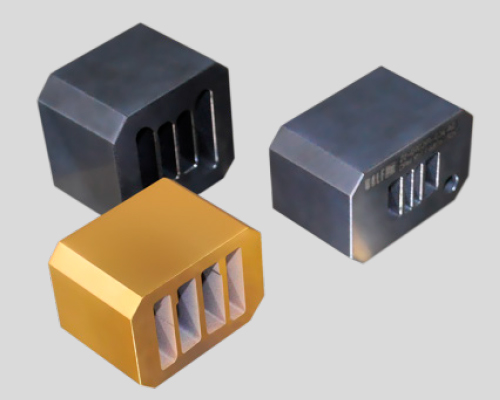

Punching And Forming

For optimal production processes

Various PVD coatings are used in punching and forming for application on tool components. While a hard coating is required to protect the cutting edge during the cutting process, various PVD coatings are applied for the complex forming processes.

|

|

|

|

PVD coatings for punching and forming PVD coating for processing copper and non-ferrous alloys Universal coating of stamping and forming tools for steel materials PVD coating for the more massive forming processes of thicker steel sheets. |

Areas of application for punching and forming 1.Cutting:Cutting blades and brake tools are coated for wear protection; 2.Punching:PVD coating of stamps and dies to increase tool life in punching processes; 3.Forming:Possible PVD applications are bending, deep drawing and embossing tools; 4.Massive forming:Massive forming, hot forming and forging are marginal PVD applications. |

Advantages of PVD coatings for punching and forming Wear protection coating for increased tool life of stamping and forming tools Improved surface and cut surface quality by use of coating Reduction of friction, adhesion and material build-up during application Reduction of lubricant use to the extent of dry forming processes Increase of stroke rates during stam- ping and reduction of drawing steps during forming. |

Get Free Quotes

Please fill in your contact information (the information is confidential and will not be disclosed to the public), we will contact you as soon as possible.

Contact

Address : Boyun Innovation Industrial Zone, 346# Leifeng Ave,Yuelu

Tel:+86-0731-88122789

E-Mail :pmcarbide@csu-pm.com

Copyright © Hunan Boyun-Dongfang Powder Metallurgy Co., Ltd 湘ICP备 050020818号

www.300.cn

Leave your contact information and we will get in touch with you in five minutes!